Rewinding & Repair

Online Help!

+91 98427 99939

DELTA ROTO TECH

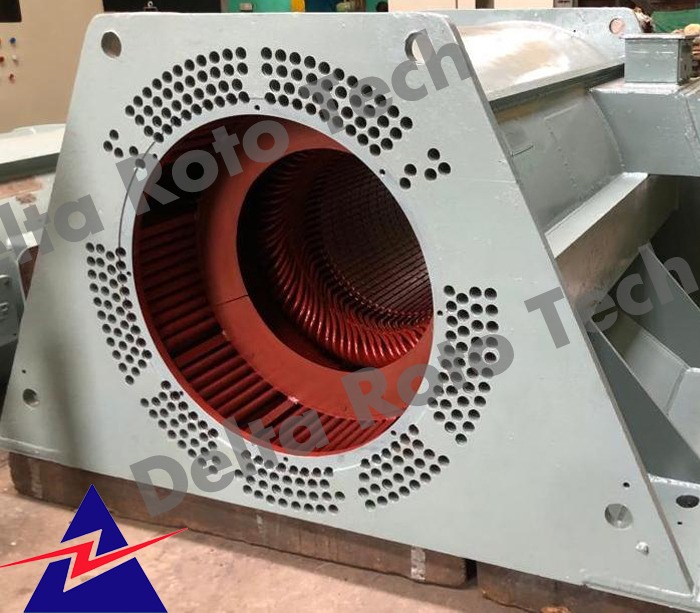

The electrical rewinding shop is equipped with VFD Operated Coil looping machines, Cylindrical Coil former’s with Skew, coil taping accessories, Hydraulic coil moulding machine, high temperature ovens, advanced testing and measuring instruments like digital insulation testers, digital micro-ohmmeter, ac & dc high voltage test kits, automatic tan delta and capacitance measurement kits, surge comparison testers, test beds etc.

We are equipped with the latest Infrastructure and Highest accurate testing devices, which keeps us ahead in providing Quality services for

- LT Motors and Generators Rewinding – Stator and Rotor

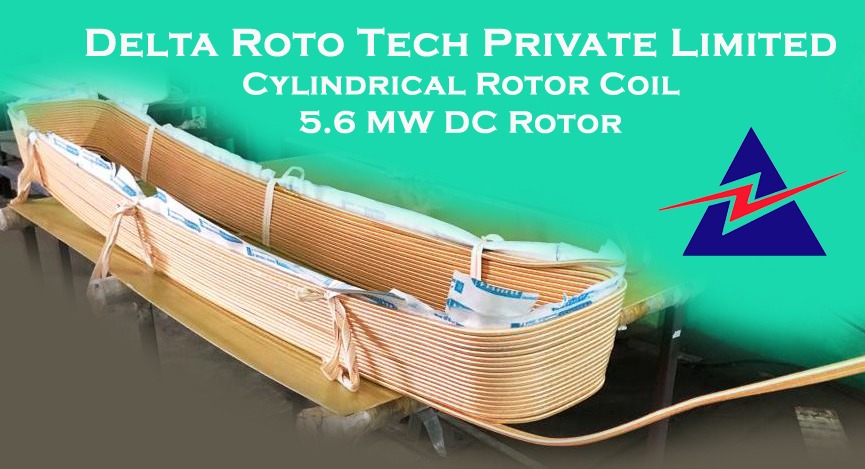

- HT Motor and Generators Rewinding – Stator and Rotor

- Resin rich and poor coil manufacturing.

- Stator core restaking and new core manufacturing works.

- G.VPI Varnishing for all Stators with our 3 Mtr Dia. VPI plant.

- DC motor coil rewinding and commutator repair works.

- Motors and generators mechanical corrections and assembly.

- Motors and Generators electrical Redesigning.

- Motors and Generators onsite overhauling with Cryogenic cleaning.

- Transformer Rewinding, Re-insulation of HV/LV Coils Cylindrical Windings

- Helical Windings

- Multi- Layer Helical Windings

- Cross- Over Windings

- Disc and Continuous Disk Windings

- Aluminum Windings

DRTPL is serving from two locations

- Unit-1: LT Repair and Rewinding upto 250kW Machines.

- Unit-2: HT Motors, Transformers & Alternator Repair and Rewinding upto 6 MW Machines

Significance:

- Unit-1: LT Repair and Rewinding upto 250kW Machines.

- Unit-2: HT Motors, Transformers & Alternator Repair and Rewinding upto 6 MW Machines

- Dust free room for high precision and standard coil manufacturing Facility.

- Core Restaking and Rebuilding Services.

- Global Vacuum Pressure Impregnation Plant facility.

- Computerized dynamic Balancing Machine as per ISO 2005 Standards.

- Standard Quality plan for Machine repairing.

- Accurate Mechanical correction and rebuilding facilities.

- In-house No-load test facility at 440V/3300/6600/11000 V Facility.